Building with Breeze Blocks

We redefine possibility by combining imagination with precision.

Overview

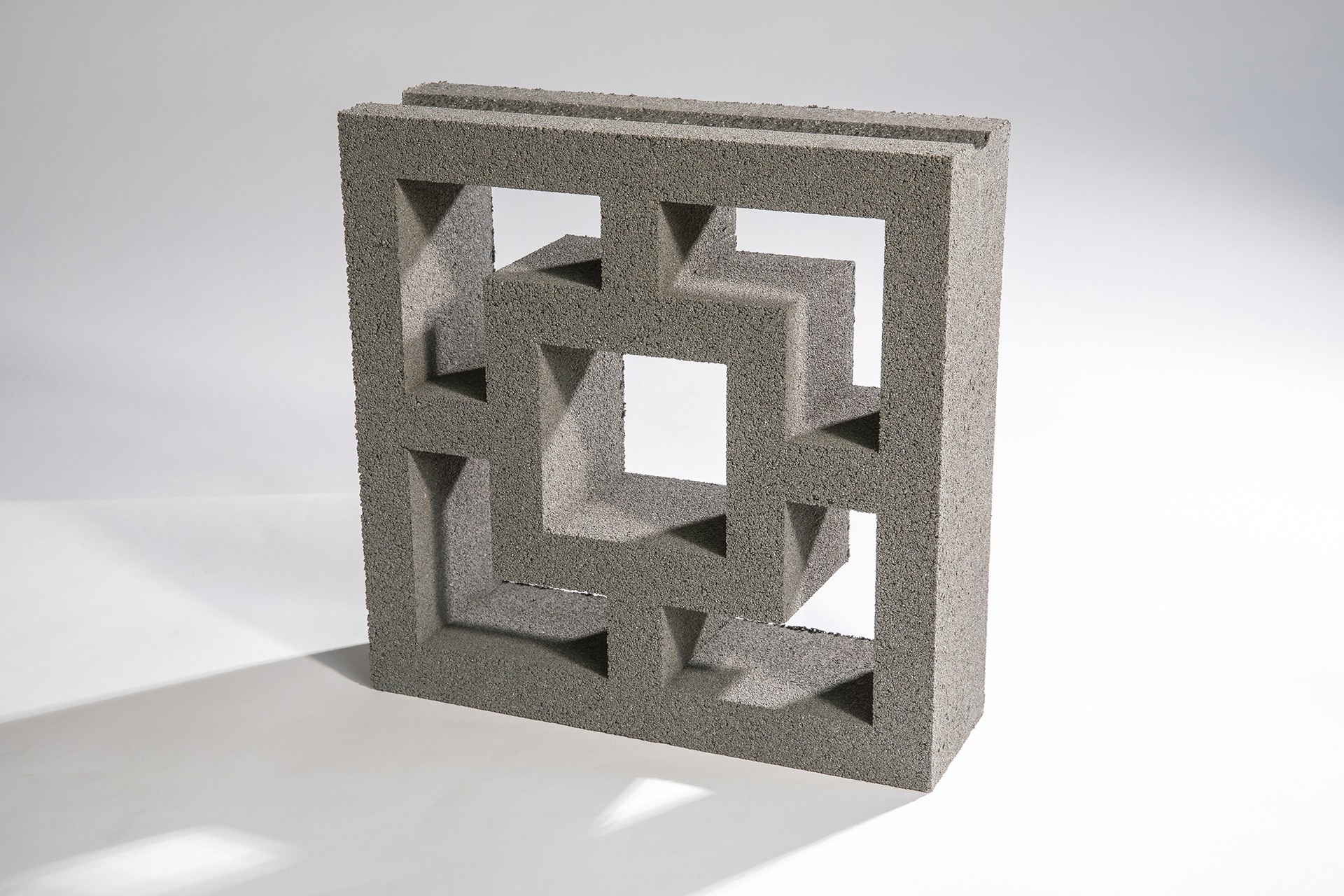

Most of our products come in a 290 mm x 290 mm x 90 mm format with varying voids in the blocks depending on the pattern. Due to the composition of the blocks they are not suitable carrying structural loads and should be used as decorative screens only.

It is important to have the right advice for any installation to ensure the installation is first and foremost safe. Once the necessary level of comfort is achieved through consultation with your bricklayer and/or engineer you then need to ensure the built outcome matches the design requirements.

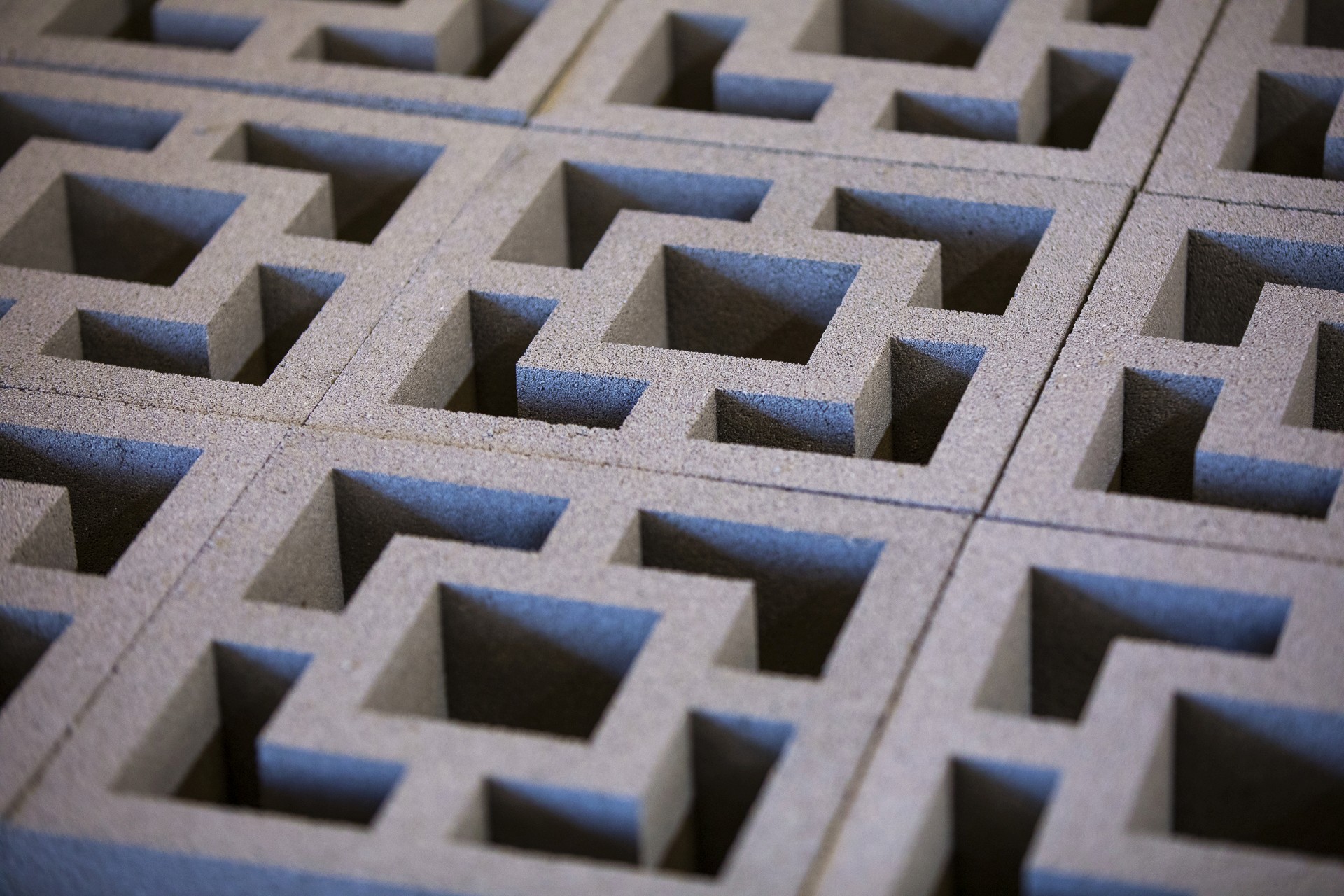

While there are many applications for our breeze blocks, the most common application is external and internal screen walls. We have developed our blocks with special rebates on two perpendicular edges to enable a wall to be assembled that can accommodate reinforcing steel in the mortar joints for stability.

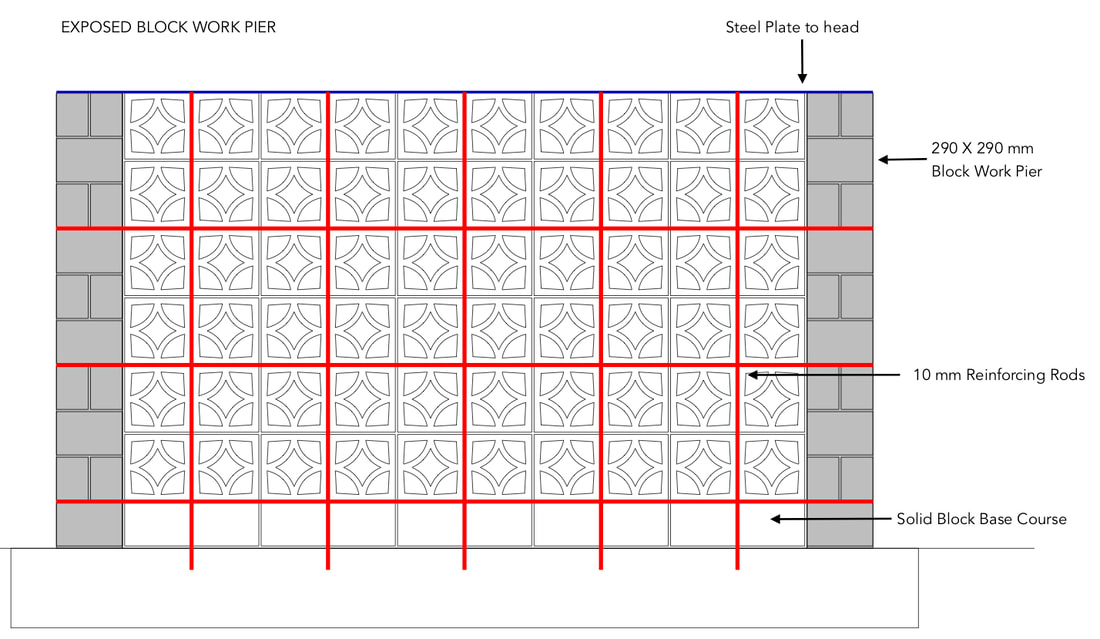

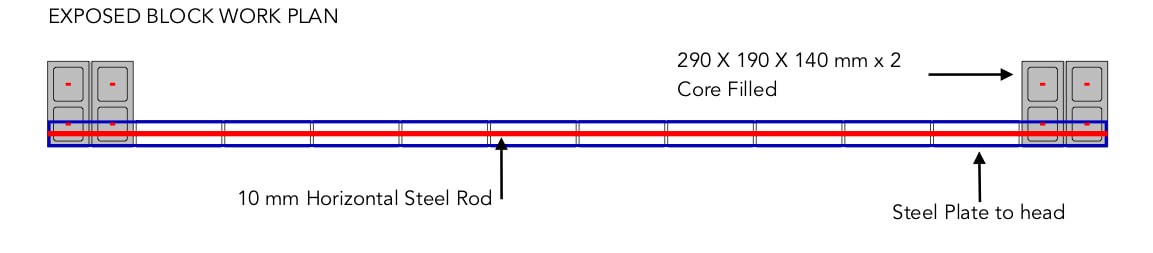

While every application is different, the diagram below sets out an example of how a wall assembly might be fabricated to provide you with the visual and structural outcome you need. Please do not hesitate to call us to discuss your ideas so as we can work with you to make it come to life.

Recognising that a good portion of the application for our products relates to fences and screen walls we have set up the following outlines for how these walls might typically be composed using a number of different approaches.

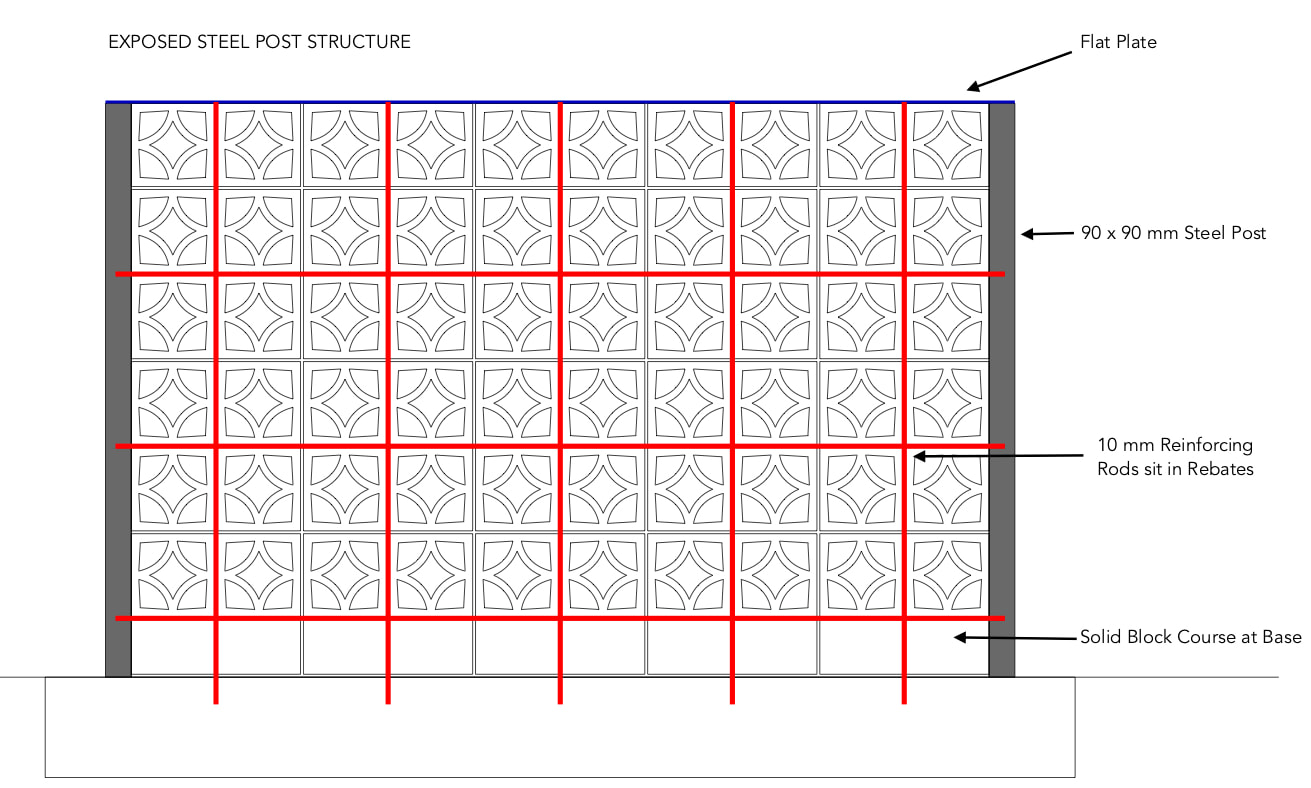

Exposed Block Work Structure

This is a very common installation method where block work piers are installed using 290mm x 190mm x 140mm blocks which work to three course for each block work pier to every two of our breeze blocks.

This approach enables steel reinforcing to be placed in corresponding joint lines which provides the necessary lateral restraint.

We recommend fences are created using a solid block base to elevate the breeze blocks from ground level as they tend to collect leaves and dirt and require regular maintenance.

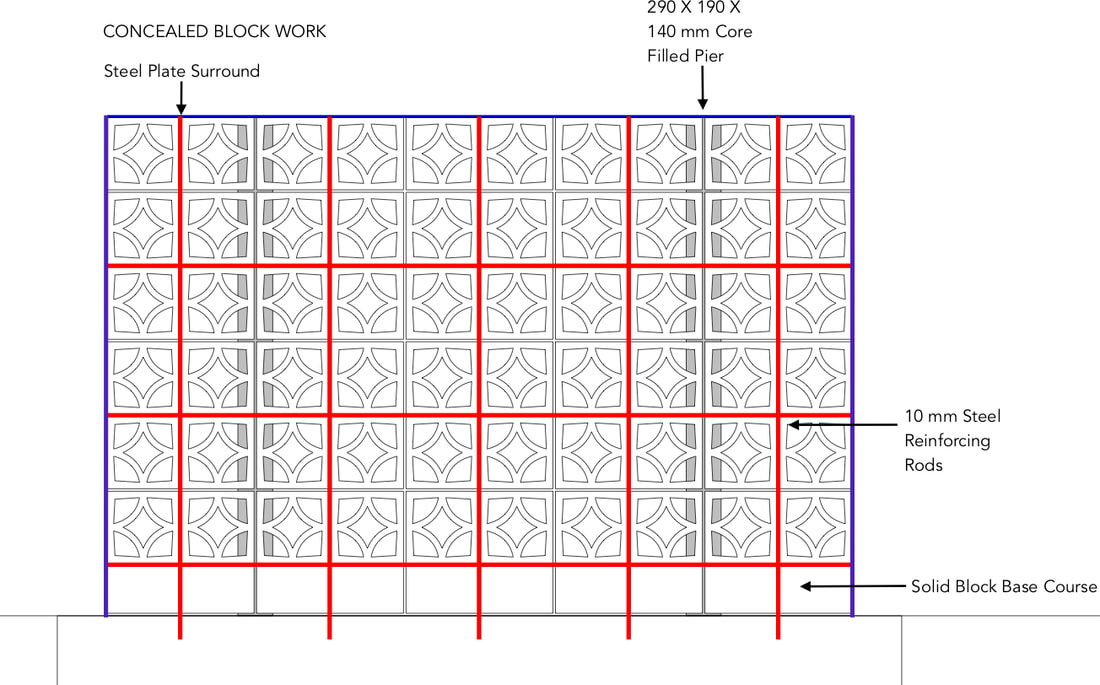

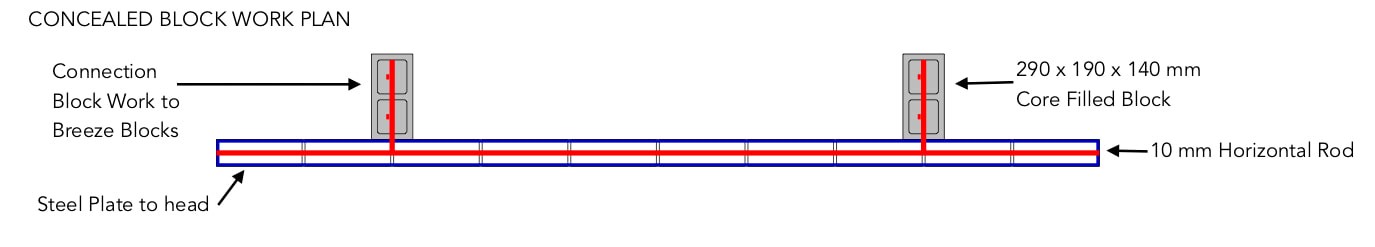

Concealed Block Work Structure

Recognising that visible structure can interrupt the aesthetic of a breeze block wall we have developed an approach that may differ from installation to installation however the principle provides the vertical support to which the breeze block wall can be connected with no visual interruption.

This involves using concrete blocks built up behind the wall in conjunction with the breeze block wall and connected at a series of points with brick ties. The concrete piers that are created would ultimately be filled with concrete typically

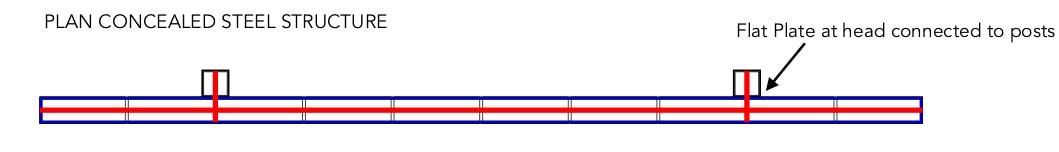

In order to tie the whole assembly together as a free standing element, the top and side flanks of an installation could be surrounded with a flat plate connected to the vertical piers. This may be necessary in large installations.

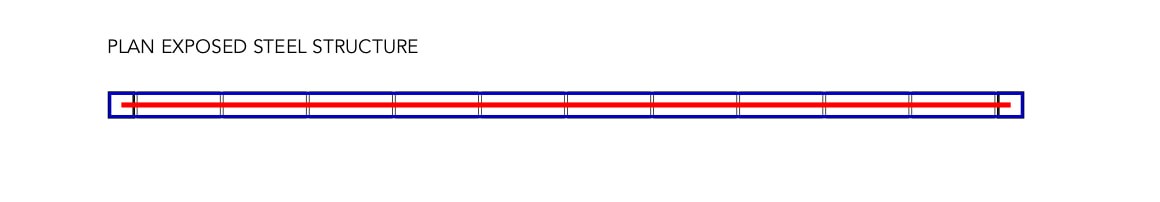

Exposed Steel Structure

Steel structure can provide a discreet outcome for a breeze block wall assembly due to the slenderness of the vertical elements into which the breeze block wall can be tied.

Steel posts can be used to connect steel rods running through the mortar joints to brace the assembly. This can be further enhanced with a capping plate to tie in the overall assembly.

Concealed Steel Structure

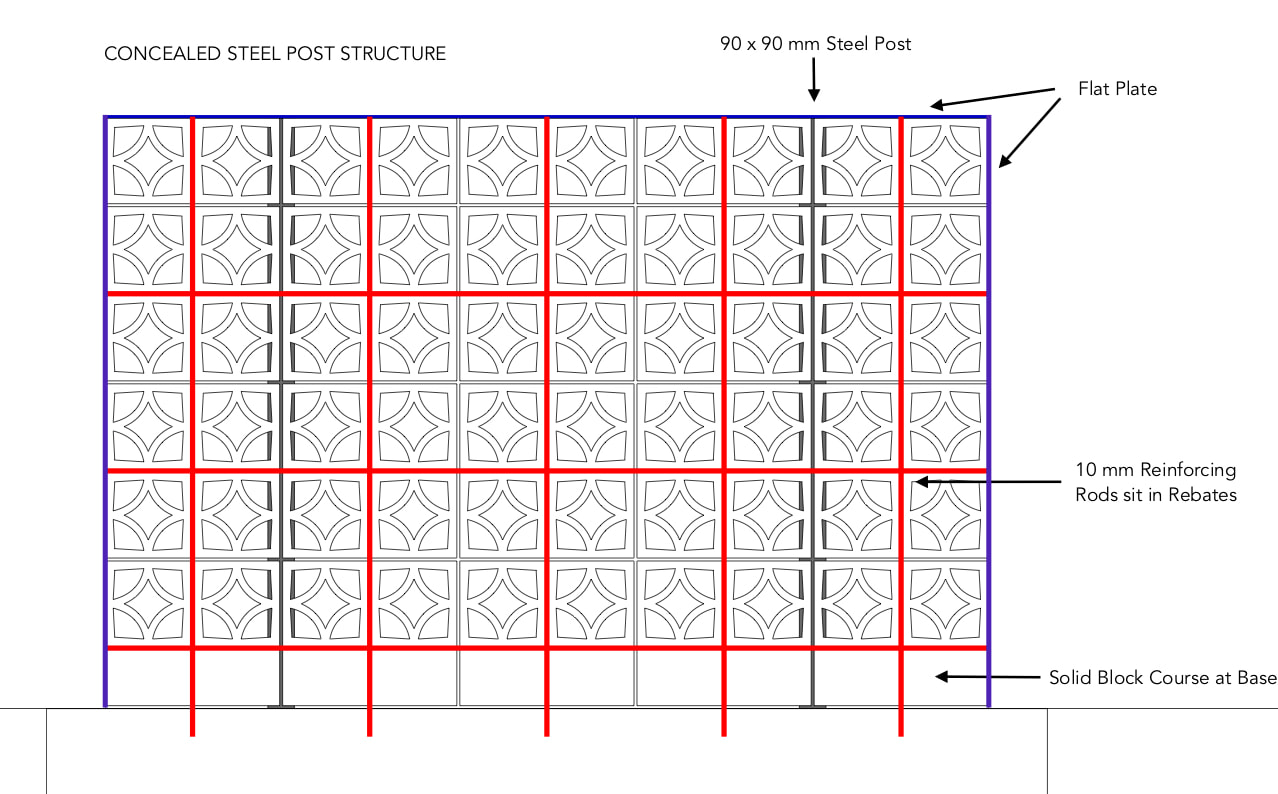

For more discreet structural outcomes we have developed a design to provide a sound structural framework for larger installations that minimises the visual impact of the structure.

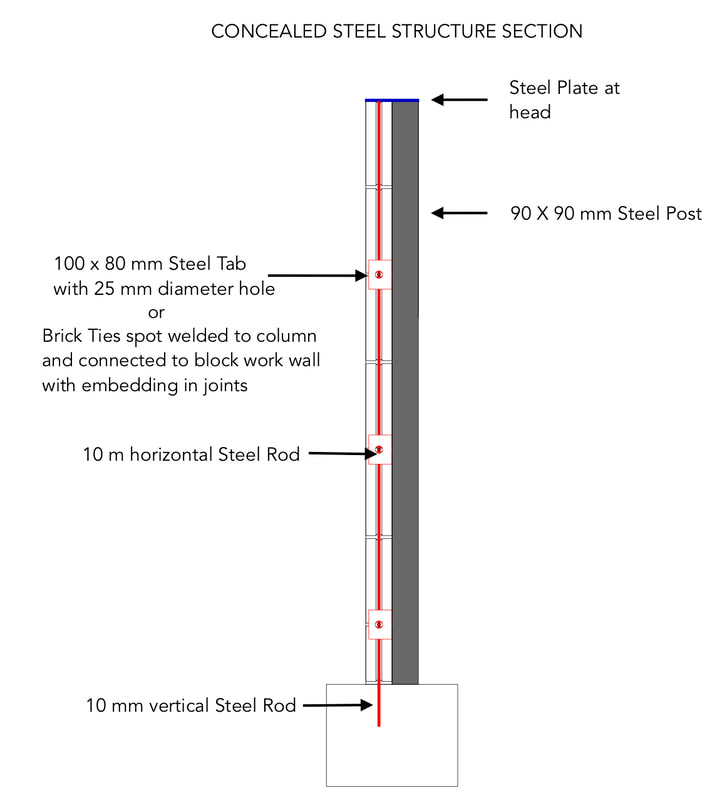

This is a system where the wall is supported by vertical steel columns sitting behind the block wall at suitable frequencies that have strategically located tabs that tie the block work wall to the columns.

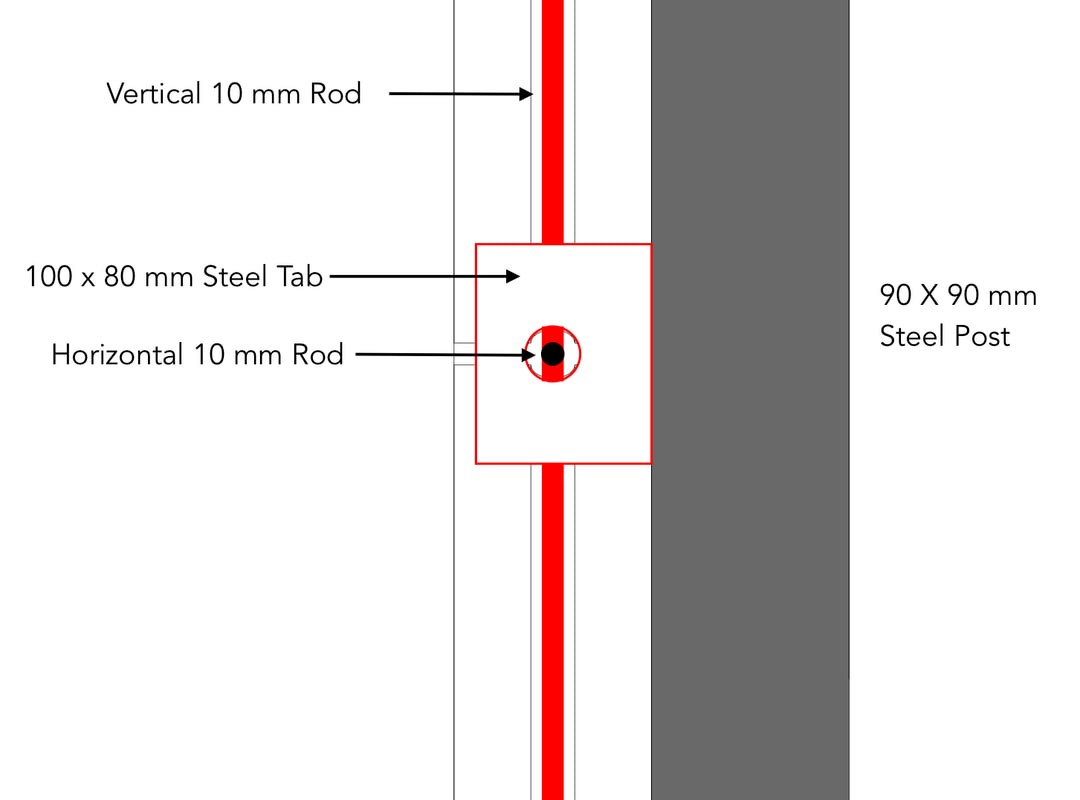

This can be done with either brick ties spot welded to the columns and inserted in the block work joints or steel tabs fixed at intervals of 600 mm protruding into the vertical joints.

These tabs have a large holes which provide a void for structural steel rods to run through every second course or 600 mm.

This housing of the structural steel rods that run through the mortar joint in every second course effectively ties the block assembly to the vertical posts.

Concealed Steel Structure Section

Designing Success